Hi Turkotekers,

Since I am affected by a

strong case of «l’esprit de l’escalier», I realize only now that I have

not answered convincingly enough Dinie’s and Steve’s

concern:

Quote:

«

I have read that it (indigo) does not really

penetrate the fiber, but forms a kind of coating on the outside. That was

why jeans fade so well and why a green made by dyeing blue over yellow,

tends to become yellowish. Indigo rubs off. Is this

correct?»Dinie’s remark in a previous post is partly correct:

Even seasoned denim dyer’s do indeed believe and write,

erroneously, that indigo stays all on the surface of the cotton

fibre, forming layers of pigment and that it is the cause of the peculiar

fading of jeans. By analogy many ruggies believe that indigo sits on their

favorite rug surface too.

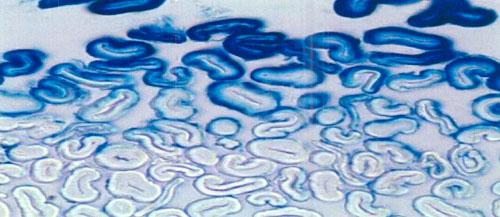

In fact, as this

micro-photography of a cross section of a denim warp clearly shows, even

in a dyeing process specifically designed (*) to keep reduced indigo

(«leuco») from penetrating too deeply into cotton, the external individual

cotton warp fibrils are indeed penetrated by the dye, which forms a

so-called «ring dyeing». The very short contact time and low dyeing

temperature explain that the dye-bath only wets properly the external

fibrils of the warp, but even under these, purposely unfavorable, dyeing

conditions the leuco molecule quite easily penetrates any single cotton

fibril which it is allowed to meet.

The picture also shows a few

agglomerates of «surface dye» (for example on top of the first fibril on

the left). Given the low affinity of leuco for cotton, its strong tendency

for premature oxidation (back to indigo pigment) and the peculiar dyeing

process, a significant amount of indigo on the surface is unavoidable.

However most of it is eliminated from the warp yarn at the end of the

dyeing process, during a two-steps (hot & cold) wash-off

operation.

The famous «stone-washing»

performed on the jeans garment

is something different: It is a severe treatment of the textile

surface with pumices, which rubs-off some of the surface

fibers and

the ring dyeing of others fibers, showing the white parts.

A mere

elimination of indigo agglomerated on the fibre surface would not call for

such a hard abrasion.

In dyeing of rug wool with indigo, the

pre-industrial dyer did his very best to avoid deposits of pigment on the

yarn surface (thoroughly pre-wetting the wool to get air out of the fiber,

keeping it under the dye-bath surface to avoid contact with the foam of

indigo pigment which usually floats on top, agitating only very gently the

fiber, to avoid carrying air into the dye-bath, keeping the pH and the

reductive power of the dye-bath high etc.). In old recipes, one often

notes that deposits of surface dye eliminated during the final

washing-off, leave colorless spots on the fiber. No doubt one of the

causes of the typical abrash of indigo-dyed wool.

Besides, wool dyeing

conditions are much more favorable to leuco penetration into the fiber

than it is the case in cotton denim warp dyeing. Although each indigo wool

dyer seems to have his own recipe, the dyeing temperature averages 50°C

(instead of 25°C) and the dyeing time averages 30 minutes for each dip

(instead of 30 seconds).

(*)

the cotton warp yarn is dipped for

less than 30 seconds in a leuco dye-bath, at room temperature, «aired»

(exposed to air) for 60-80 seconds and this process is repeated, on

average, 6 times)Hoping that you have all recovered from

season excesses,

best regards

Pierre