As I mentioned in another post, Hans Wulff treats felting under the term “fulling” in his very extensive “The Traditional Crafts of Persia.”

Wulff says many of the things about felt and how it is made that other authors do, and agrees with Barber that felting is primarily a mechanical process in which the “scales” and the “crimp” in wool work to entangle the fibers inextricably. Barber says explicitly that felting is not a “chemical” process like paper-making, but Wulff points out that sometimes “chemicals” were used in felting to enhance the natural capabilities of wool.

“…This interlacing process becomes stronger if so-called fulling agents (such as alkalines, ed. read "soap," and fuller’s earth) are applied. Mechanical working, called hardening, accelerates the integration of the fibers.”

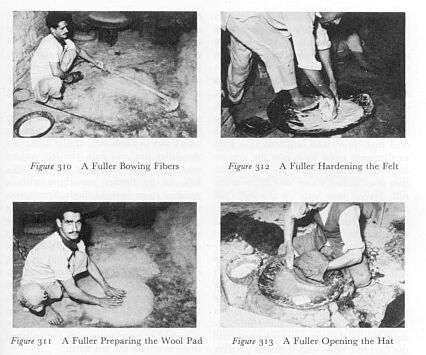

Wulff also gives a detailed description and a few pictures of “hat felting.”

“Wool (pasm), often mixed with goat underhair (kork, kolk), is degreased with potash, rinsed, and after drying combed (saneh zadan) on a wool comb (samej) or loosened with a bow (kaman zadan), Fig. 310. (ed. “bowing seems to play the same role as “carding,” i.e. to fluff up the wool fibers). A circular layer of this wool, a so-called bat (angereh), about twice the size of the finished hat, is spreadd (vaz kardan) in even thickness over a shallow copper dish (taveh, touveh, Fig. 311) that is mildly heated from underneath by a charcoal fire. The fuller (gazur, qassar, namad-mal), or kolah-mal if he is a hat fuller, sprinkles this bat with a thick soap solution (ab-sabun) from an earthenware dish beside him. While wool and soap water warm up, he presses the fibers with his hands, first gently, then harder and releases them again. As soon as the felt begins to form he places a flat cotton pad into the center of the bat, approximately the sized of the required diameter of the hat. He lays a second bat of beaten wool, smaller in size than the first one, over the pad and folds the surplus of the larger one over, thus joining the two halves (lab gereftan), then saturates the whole in soap water. After he has squeezed it mildly for awhile he places it on a piece of cotton fabric and rolls both, prefelted bats and fulling cloth, into one roll, thus preventing interfelting. He puts this roll back on the dish with warm soap water, where he rolls it backward and forward with both hands and one foot (Figure 312). This hardening (namad malidan, malidan) operation takes about 10 to 15 minutes, after which the fuller carefully unrolls the felt, tears the center of the hat apart, widens the opening (baz cidan, Figure 313), takes the cotton pad out, and forms the opened part into a rim (guseh). From time to time he pulls the felt over a wooden block (qaleb zadan), perfects the rim and places the whole back into the hot dish for further shrinking (mosteh sodan) until it obtains the shape of a hat and the required density. During the process thin patches are overlaid with little wool bats and these are worked in. If the fuller works in a small village he immediately proceeds to finish this raw felt into a hat, but in the larger communities this is left to a specialist, the hatter. His work will be described in the following section.”

Wulff does in fact describe how the hatter continues in a separate section but, oddly, first provides the following passage on some non-hat felting processes.

“Large felt rugs, tent coverings, cloaks, and blankets are worked along similar lines except that the large wool bats are placed on the ground (ham kardon) and are sprinkled with soap water, after which the fullers walk over them to achieve the first interlocking (pasm gereftan), usually several of them walking side by side and working the wool with their bare feet. The mildly compacted bat is rolled up in a canvas or reed mat (hasir) and placed in a long earthen ware mold built into the ground and heated from underneath. In Horasan they pour boiling water (ab-e jus) over the roll. Several men walk on this roll (puk kasidan) and turn it over with their feet while they lean against a wooden bar at waist height. For large rugs and tent covers it takes several hours before the rug is sufficiently dense. Most of the nomadic people like their felt rugs with colored ornaments (gol). They dye (rang kardan) the wool prior to fulling, do the first stage of fulling in one color, open the roll, and place wool of different colors according to the ornaments planned onto the felt base, often with different patterns on the front and reverse, and continue with the fulling. The ornaments become an integral part of the felt. After the fulling, soap and fuller’s earth (sang-e qibti) are washed out, the felt is dried, and if used for tent covers, waterproofed with animal fat.”

We can see in these descriptions some obvious similarities to others. The “dance” of the single felter in the video appears in a version for large pieces and several men (notice not women here). And there is an analog of the single felter’s supporting “cane” in the wooden bar for leaning.

But there are also differences. The enhancing chemicals and the “long earthen ware mold” are new features and at the very end no chances are taken that a tent felt will shed water. Animal fat is applied.

Regards,

R. John Howe