Hi all,

Mike’s post and his remark

«The Mordant is the key. Aluminum for crimson, Tin for bright scarlet,

iron for violet, grey, and black» is a welcome pretext for me

to mention another, very rare, Turkmen (Salor?) shade: grey.

But

first please allow me a short general remark about pre-industrial black

and grey shades on rugs and textiles.

It is highly unlikely indeed that

black and grey shades were ever made with a recipe using cochineal, for

two main reasons:

It would be very wasteful indeed to use expensive

cochineal and iron mordant to make a black or a grey.

Besides, it would

not even be easy to achieve these shades with this recipe (1).

Cochineal/iron is only a sensible choice to make subdued purple and violet

shades.

Pre-industrial dyers achieved black and grey with one of

the following recipes, mostly using natural grey of brownish wool as a

base:

- Un-dyed natural grey wool, shaded if necessary. (But,

apparently, not natural black wool (5))

- Tannin and iron salts. (The

cheapest way for a black shade but potentially leading to wool

degradation. The range of black shades achievable is a bit limited).

-

Tannin and iron salts on wool previously dyed with indigo in a deep blue

(More expensive, but giving a large range of black shades. Due to the more

limited usage of iron salts the risk of wool degradation was much lower

too. This was the recipe agreed by King Louis XIV’s nosy bureaucrats for

«Grand Teint» black shades (High fastness quality). Similar regulations

applied in other countries as well.

- Wool dyed with indigo in a very

deep blue (surmey), then «shaded» in a second dyeing operation with madder

and / or a natural yellow. The most expensive recipe.

However, a

few modern Afghan Turkmen dyers still know that a natural dyestuff which

they call "ela-rang" , Alkanna tinctoria in Europe (2), yields beautiful

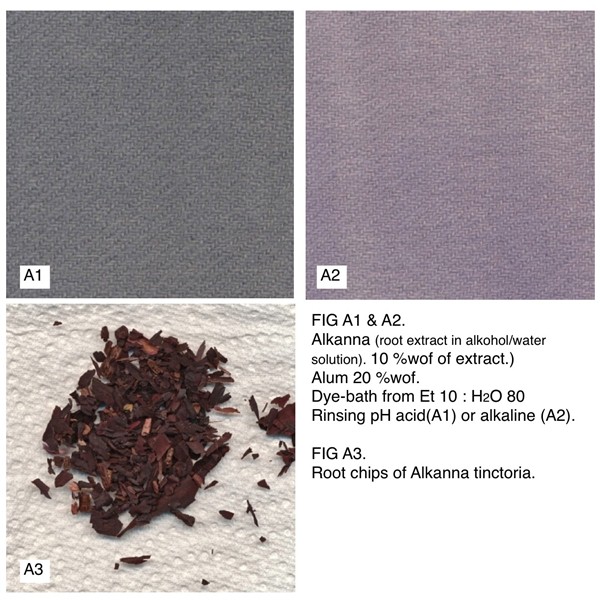

grey shades with bluish or violet cast (3). FIG A shows two examples of

shades dyed with alkanna root-chips on alum-mordanted wool.

FIG

A.

I

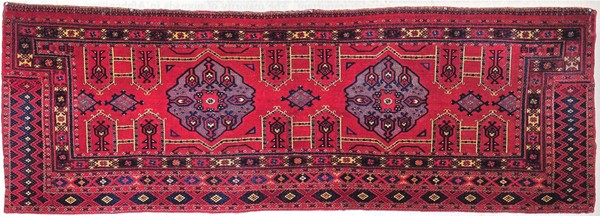

would not be surprised if the analysis of the Salor rug below (published

in Opie’s «Tribal Rugs») and of some of his extant friends would reveal

that the dye used for the pile of the gul was alkanna. IMHO this

particular shade of grey would be difficult to obtain with any other

natural dye recipe. Proof of the contrary is much welcome.

Neither would I be

much surprised if the main users of Alkanna would have been central Asian

Jews: The dye is poorly soluble in water (thus difficult to use from an

aqueous dye-bath) but very soluble in alcohol / water mixtures. Jews were

often the only central Asian ethnic group allowed to make alcoholic

beverages. For their own consumption only (at least officially

). This was the case in nineteenth

century Bokhara for example. And of course they also were often mentioned

as competent dyers, especially involved in the indigo

business.

(1) The Turkmen weaver who complained to Madame

Moshkova that he would only obtain grey shades with cochineal was probably

merely «dyeing» his wool with a dirty component extracted from the insect

shell, while all the red carminic acid was precipitated and made unusable

by the calcium present in his hard water.Many users of

cochineal dried insects know that during the initial minutes of the dyeing

operation this impurity comes out, quickly goes on wool and soils it.

Therefore, pre-industrial dyers often sacrificed a few skeins of

low-quality wool in the dye-bath to get this dirty «dye» out of it. When

this purification was completed they introduced the wool they wanted to

dye bright red. (2) Source: Marc Roy. Private

communication.(3) The roots of Alkanna tinctoria (Anchusa

tinctoria, Dyer’s bugloss) and a number of other Boraginaceaes (4),

contain a high concentration of a strong dye («alkannin», a naphtoquinon)

which on alum-mordanted fibres yields a variety of grey shades on wool and

subdued violet shades on cotton. I have seen «bishop violet» shades

achieved on wool too (but I haven’t yet found the trick). The light

fastness is not good while probably still sufficient for

rugs.(4) D. Cardon . Natural Dyes. Pages 60-66.(5)

Natural black wool is said to have poor light fastness. I have not yet

verified this information.Best regards

Pierre