Home Page Discussion

The Salon du Tapis d'Orient is a moderated discussion group in the manner of the 19th century salon devoted to oriental rugs and textiles and all aspects of their appreciation. Please include your full name and e-mail address in your posting.

Mini-Salon 26: The Quest for the Bright Salor Red

by Pierre Galafassi

The best Salor red is that of highly oxygenated blood squirting out of a big artery, is how Jim Allen described the surprisingly bright red shades of some rugs attributed to the Salor (1). He should know, having been intimate with quite a few of them in his long career. Before the introduction of synthetic dyes, the Salor arguably made the brightest of all Turkmen reds, only matched, perhaps, by the rich red of some 18th century Caucasian "dragon rugs". How did they do it? I thought it would be fun to try to identify their process, then look for a credible explanation for its failure to diffuse to other Turkoman weavers (9).

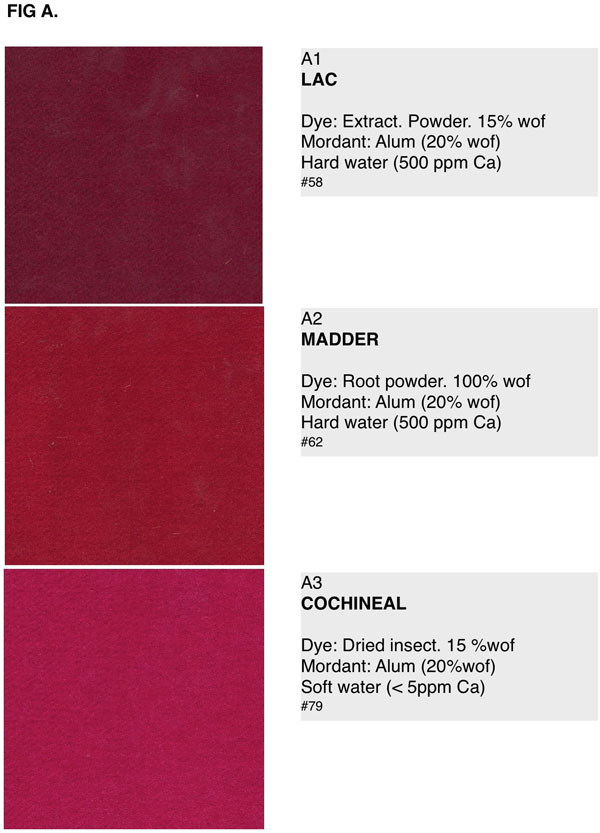

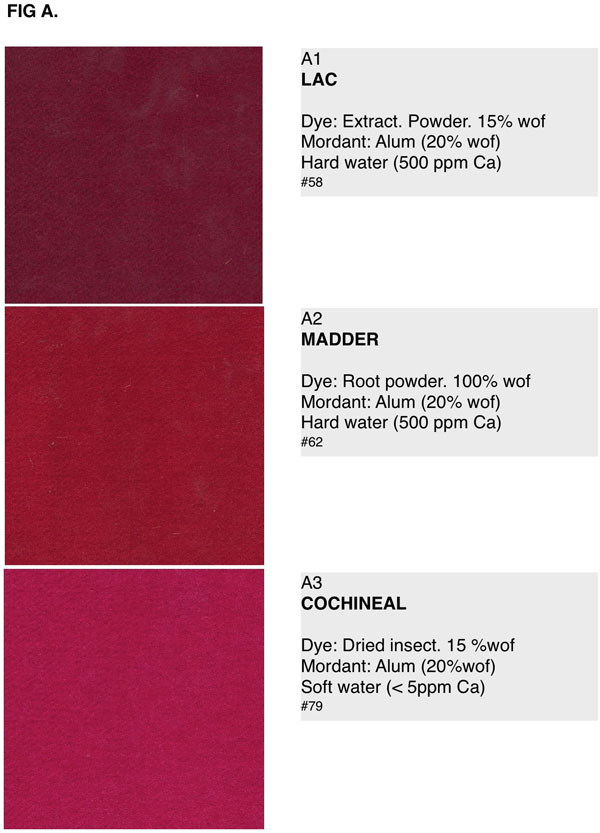

Awhile ago it was suggested that Salor were involved in selling and diffusing the Indian and Chinese natural red dye, lac, in the region (2). Whatever one thinks of this rather creative hypothesis, the lac dye cannot have led to bright red shades, as can be seen in Fig. A,which compares lac with Rubia tinctorum (madder) and cochineal. Lac yields beautiful, but rather subdued burgundy shades with alum mordant and no other mordant can make it brighter.

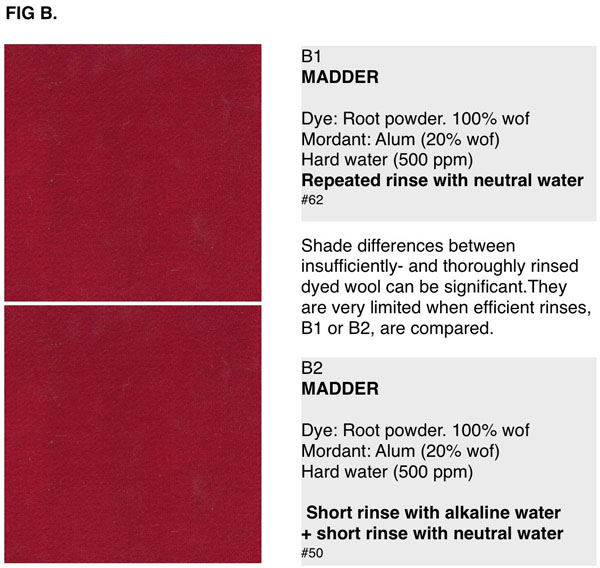

Another well known blogger once claimed that a Persian master-dyer told him that the secret of the bright Salor red was in using madder with a very alkaline desert plant in the dye bath that affected the color and made it bloom (3). Something must have been lost in translation: although many dry-steppe plants supply highly alkaline ashes which were probably used quite often by Turkmen and other Asian weavers in the rinsing bath that follows dyeing (4), alkalinizing wool that has been dyed with madder pushes the shade a trifle bluer but, alas, not brighter, as can be seen in Fig B.

Complete "hot" dyeing (not just cold rinsing) of wool with madder in an alkaline dye bath would wreak havoc in the fiber, making it brittle and "corrodible", and would yield even much duller and brownish shades instead of red (5). So, I am afraid, this information appears to be a red herring.

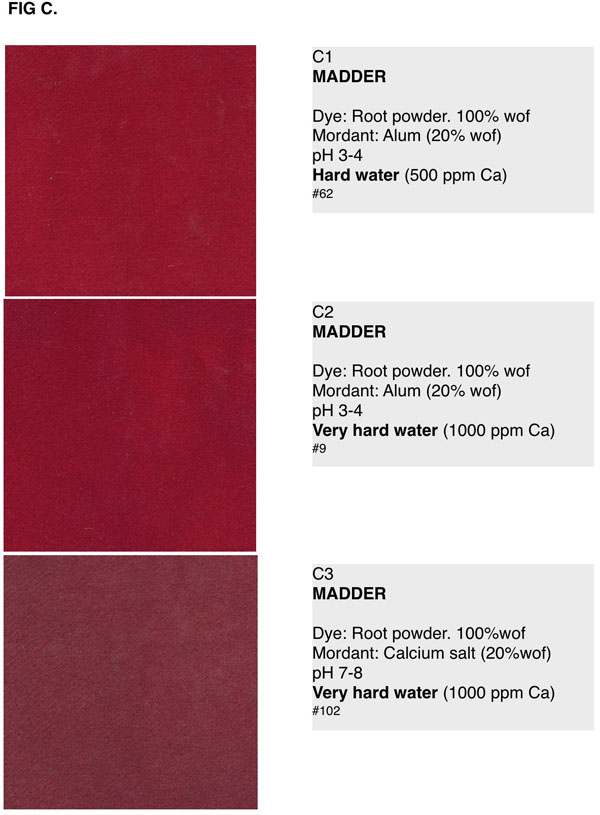

Laboratory testing of the various solutions that the Salor may have had at their fingertips quickly eliminated one of my own candidates, too: using soft water instead of hard water (calcium and magnesium-containing) for dyeing. This hypothesis did not seem too hare-brained at first. It is a fact that introducing increasing quantities of calcium or magnesium salts in the mordanting- or dyeing bath makes the shade of madder increasingly dull and drifting from red toward brown.

It is also a fact that the area the Turkmen call home is predominantly calcareous (6). Their wells and rivers are, therefore, likely to provide mostly hard water. Thus, in theory, one could expect that dyeing wool (with madder) in soft water should yield brighter reds than dyeing in the kind of hard water normally available in the whole region.

How could the Salor have obtained soft water? Well, for example, by melting snow or using rainwater accumulated in the many clay-lined depressions dotting the Qara-Qum (reported by most 19th century travelers) or using water from a river coming from a noncalcareous mountain range, if there is one nearby (7).

Unfortunately, soft water alone cannot be the secret of the Salor red. Lab tests show, at best, only a minor increase in the brightness of madder dyeing when using soft water rather than the kind of hard water (around 300-600 ppm?) presumably available to Turkmen dyers.

The next hypothesis was more successful. It is well documented that pre-industrial (17th-19th century) European dyers routinely used tin salts or a mix of tin salts and purified (iron-free) alum as a mordant when dyeing with madder and cochineal in order to obtain brighter red shades on wool (8). These master dyers were perfectly aware that even traces of iron salt in the dye bath would ruin the shade, making it duller. Therefore, they used tin-lined copper vessels, good quality tin salts and only purified, iron-free alum when they used alum at all. There is no reason to think that the Salor could not have made this discovery too, perhaps even before the Europeans did. Many inhabitants of central Asia traditionally used copper pots lined with tin for cooking, and tin was easily available.

How could the Salor have enjoyed a monopoly on this process?(9) Perhaps being an aristocratic and exceptionally competent tribe of caravan robbers (10), at least until their defeat against Persia in 1832 (11), they easily could have bought or robbed tin, tin-lined copper pots and iron-free alum from Persian or Bokharan merchants. During the entire 19th century, cheap Russian cast iron vessels were predominantly used by many Turkmen tribes, especially the Yomud and the Chodor (who, incidentally, are known for their preference for predominantly dullish red shades), and also by their Kazakh neighbors (12).

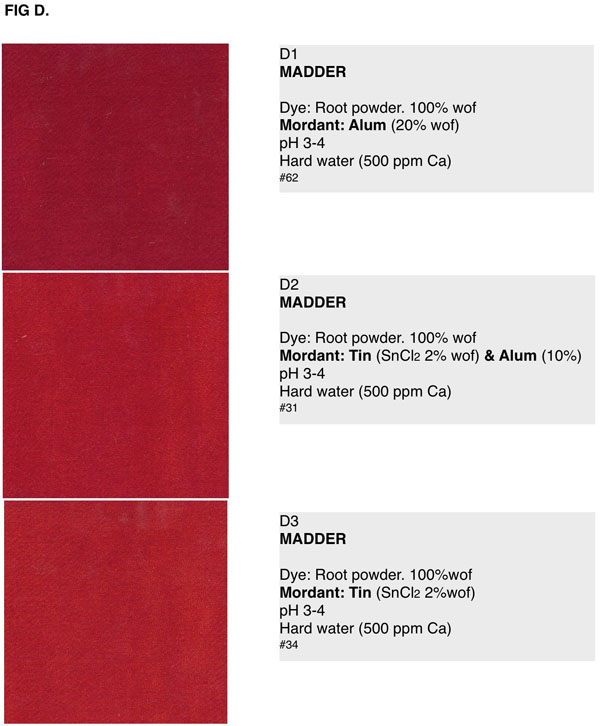

The lab tests indeed confirm that significantly brighter red shades can be obtained with madder on tin mordanted wool (13), compared to alum mordanting, as every modern cottage dyer will tell you.

Even brighter shades of red can be obtained using tin mordant together with mixes of cochineal and madder, or, better still, with pure cochineal.

However, as cochineal can only dye wool in a soft water dye bath (no calcium or magnesium) the Salor dyers must have had access to this rare item (soft water), and, unlike most other Turkmen (14) must have known this little secret of cochineal dyeing.

Conclusion: Mordanting with mixtures of tin salts/alum or with tin salts alone yield brighter shades of red with madder, and even brighter shades with madder/cochineal mixtures or cochineal alone. The necessity of avoiding even traces of iron salts was certainly well known by all Turkmen (who purposely used variable proportions of iron/alum mordants with madder to achieve various brownish reds and dull aubergine shades (15)). The need for soft water for proper dyeing with cochineal was obviously known by the Bokharans and could have been known by at least some Turkmen dyers as well. All ingredients needed to achieve these bright reds were available to Salor dyers.

Occam's razor would, therefore, suggest that tin mordanting was the secret of Salor dyers. In order to confirm this theory, an analytic assessment of tin in bright red shades would be necessary. Unless I err, so far only an assessment of the dye was performed in a few cases and madder was found.

NOTES:

Warning:Communicating true shades from PC to PC is only possible with expensive professional hadware and software. Depending on the quality and calibration of each screen (among other parameters), every reader will see slightly different shades. Sorry!

(1) Turkotek, May 14, 2010. Discussion of Salon 132.

(2) Turkotek. J. Allen, January 23, 2008. Discussion on Tekke tertiary gul: ... Nobody knows for sure why the Salor were the main purveyors of lac dyed wool and silk in central Asia, but their weavings show by far the greatest amount of this dyestuff ...

Turkotek, J. Allen, August 25, 2007 ... The Salor were using lac to dye the fields of their main carpets a vivid purplish rose ...

Creative, but rather shaky theory which I shall not discuss here.

(3) Oriental Rug Talk, May 18, 2010. The blooming red of Salor rugs.

(4) There is a fair likelihood that all Turkoman knew how to use alkaline ashes of desert plants like saxaoul (which was by far their main firewood), to stabilize the shade after dyeing. Any madder dye bath is normally quite acid, whether alum mordanting is performed prior to, during or after dyeing proper. Rightly so, since acidity favors the dye uptake. Acidity was given by the alum itself and optionally increased by adding to the dye bath fermenting cereals (barley, "jugara"), or juice of sour grapes or some aptly named "cream of tartar" (potassium hydrogen tartrate, a weak acid, obtained by fermenting grape). Thus, at the end of the dyeing process, wool should ideally be rinsed thoroughly with lots of cold water to bring it back from pH 3-4 to a rather neutral pH and a stable shade. Failing to do so would impair the long-term stability of the wool fiber, and would also leave quite some unfixed dye on the wool surface. This unfixed dye not only has a somewhat different shade than the real thing, it could also cause the color to run later on. In steppes and deserts, where water is rare and precious, dyers were surely often tempted to replace the wasteful cold rinse with natural water with a short but effective cold rinse with alkaline water (a handful of saxaoul ashes brings water to a pH of about 10 ) to wash out all unfixed dye while stabilizing wool near its pH neutrality. The change of shade, compared to still acid and barely rinsed wool, is noticeable (somewhat duller and bluer with madder dyeing). The difference is much less obvious when comparing a short and cold alkali rinse with a cold rinse with much natural water. The trick with alkaline water was well known by European pre-industrial madder dyers, too.

(5) Dyeing wool with madder in an alkaline bath (as opposed to only performing a short alkaline cold rinse of the fiber as described in note (3) is not wise. It would mean treating wool at about pH 10 during at least two hours at 60°C or at least 45 minutes at 100°C. Under these harsh conditions, the wool polymer would take a severe beating and become brittle ( "corrodible" in Rugdom dialect). Besides, it would make the shade very much duller, a reddish brown instead of a red.

(6) As we can infer from the famous white marble mountains of the Mangishlak Peninsula, from the huge Köv-ata caves and from the underground rivers of the Kopet Dagh Mountains mentioned by H. Moser, ..Many rivers in the Kopet Dagh range, disappear underground and reappear in the Akhal Teke piedmont. The Kopet-Dagh is apparently mostly limestone and the underground therefore perforated ... (Durch Zentral-Asien, page 321. 1883-1884) and from notes of many travelers (for example, C. Zimmerman in 1840 and Muraviev in1819-1820), about the frequent occurrence of gypsum, lime, shell sand, chalk, marl and marble throughout the Turkmen country.

(7) The Zerafshan river could be such a rare case of reasonably soft-water river: It irrigates the Bukhara oasis and loses itself in the sands close to the right bank of the middle Amu-darya, in an area settled by Ersari and Salor during part of the 17th, the 18th and the 19th century (11). I have not found yet any information on the water hardness of the Zerafshan River but assume that it must be quite low (noncalcareous, soft) since Bokhara was famous for dyeing silk and wool with cochineal and this dye requires a soft-water dye-bath.

(8) In 1630, the "Dutch Leonardo da Vinci", C.J. Drebbel, an engraver and serial inventor, accidentally discovered that a tin mordant yields brighter red shades with cochineal or madder than an alum mordant.

(9) Is it so certain that all extant bright red turkmen rugs were Salor-made? Is it so unlikely that none of the hypothetical bright red rugs of other tribes (for example, the rich and predatory Merv Teke) survived until our days?

(10) A. Burnes. Travels into Bokhara. (1831-1832)

Vol II. page 49: ... Sarakhs, a large Turkoman settlement ... the greatest haunt of the Turkoman robbers.

Vol I page 338-339: Soobhan Verdi Ghilich (The-sword-given-by-god) ... was of the tribe of Salor, the noblest of the

Turkomans ...

Vol II pages 59-60: ... I was very agreeably surprised to find these wandering people living here (note: on right bank

of the Tejen River), at least, in luxury ... The tent or khirgah was spacious, and had a diameter of about twenty-five

feet ... The floor was spread with felts and carpets of the richest manufacture, which looked like velvet. ... Fringed

carpets were also hung up round the tent, which gave it a great finish ...

Burnes met Salor clans on the right bank of the middle Amu-darya and in Sharakhs (right bank of the Tejen River) in

1832, at the peak of their reputation, only months before a Persian army dispersed the latter, destroying their wealth.

After 1832 and until the Russian conquest, the title of most obnoxious Turkmen robbers was firmly held by the Akhal

Teke, followed by the Merv Teke, and some Amu-darya Ersari (Merv Teke dixit).

(11) See Turkotek Salon 132, "Location of major Turkmen tribe, 16th to 19th centuries", chapter about Salor.

(12) E. O'Donovan (1881-1882), Five month residence among the Teke of Merv... Vol I. page 171). ...Nearly every

cooking utensil used in this part of Persia is of copper, tinned inside. While Atterek Turkomans (note: Yomud and

Göklan) use more cheaper cast iron pots ...

H. de Blocqueville (1861), Quatorze mois de captivité, page 266 : Russian cast iron pots are a major import item in

Merv (Tekke).

M.N. Mouraviev and H. Moser confirm the ubiquity of cast iron pots in northern Turkmen tribes (Yomud, Chodor) as well.

(13) Tin salt used as mordant tends to build unevenly on wool and therefore may lead to abrash; it can also make wool brittle. A reasonably low concentration of tin salt in the mordanting bath (2-5% wof of SnCl2) and a very thorough rinsing after dyeing appear to be sufficient cure for the latter inconvenient. (% wof means weight of mordant as a percentage of weight of fiber).

(14). W.G. Moshkova, (Carpets of the People of Central Asia, page 38) did not mention the need for soft water when dyeing with cochineal and apparently neither did any of the Turkmen dyers interviewed during her expeditions. One of them even complained that he would obtain only a brownish shade with this dye (!). I think it is reasonable to believe that the hard water, predominant in the area, made cochineal a rather frustrating dye for Turkmen dyers. The few areas of cochineal-dyed silk or wool in Turkmen carpets were perhaps mostly obtained by unravelling old Bokharan or Persian textiles.

(15) P. Mushak. Dyes and related materials in Turkoman rugs and trappings. Vanishing Jewels, page 64, table 4.